Probing on all machining centers capable of checking dimensions and setting offsets within .0002″

CNC VERTICAL MACHINING CENTERS

Full 5-AXIS

DN Solutions DVF 5000 gen2

Travel (X,Y,Z) 25″ x 18″ x 16″

20k RPM spindle

850# work load

High speed machining

Through spindle high pressure coolant w/coolant and spindle cooling

3 & 4 AXIS MACHINES

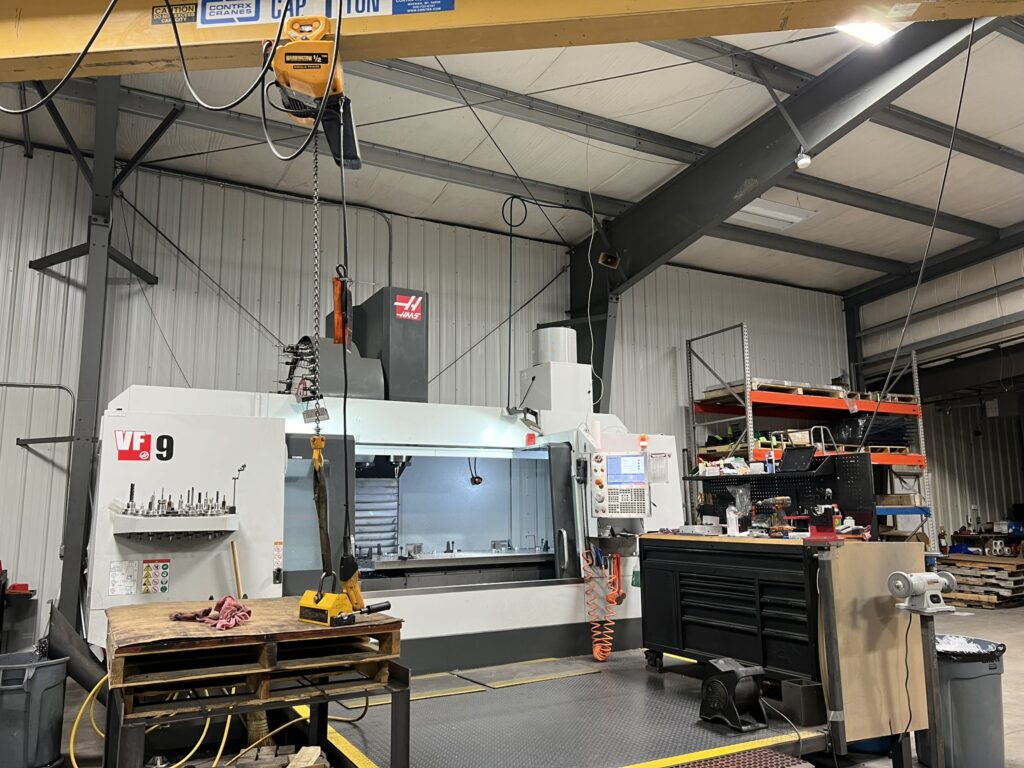

HAAS VF9 CAT50 taper

Travel (X,Y,Z) 84″ x 40″ x 30″

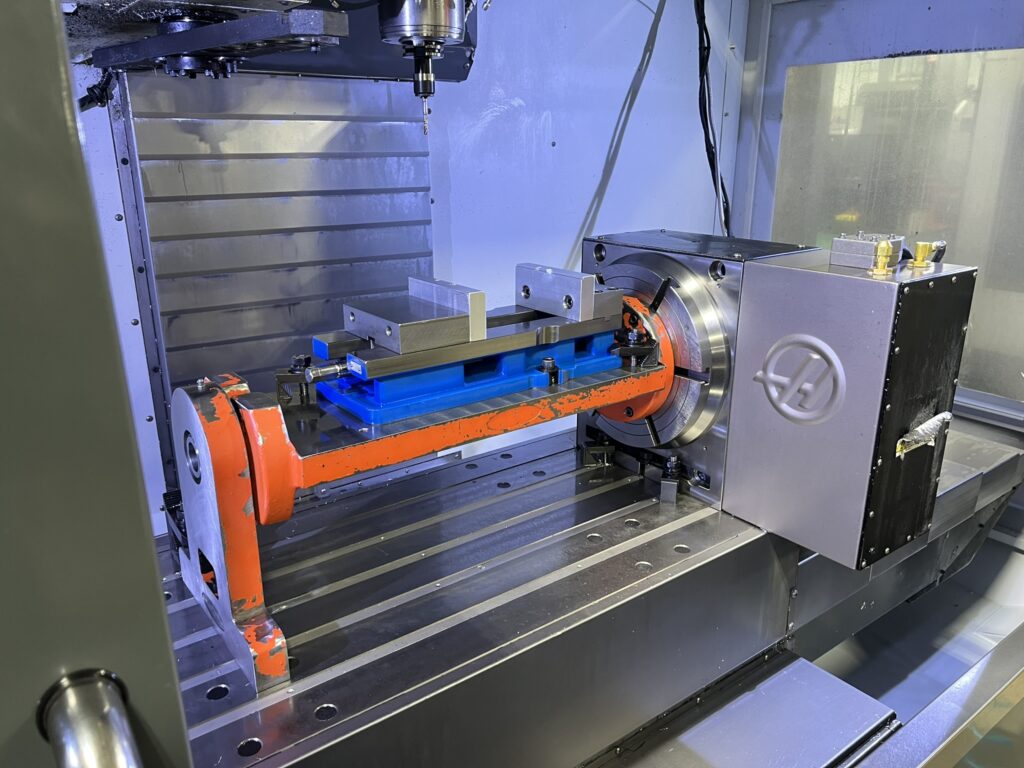

Full 4th axis

7500 RPM spindle with geared head

4000# work load

Through spindle high pressure coolant

HAAS (1)VF4 & (2) VF4ss CAT40 taper

Travel (X,Y,Z) 50″ x 20″ x 25″

Full 4th axis

10k & 12k RPM spindle

1750# work load

High speed machining

Through spindle high pressure coolant & air blast

CNC LATHE MACHINING CENTERS

PUMA DNT 2600L

20” Swing

18”x42” Cutting (dia x length)

3.2″ spindle bore

Programmable tailstock

(x2) HAAS ST35

21” Swing

18”x26” Cutting (dia x length)

4″ spindle bore

Programmable tailstock

MANUAL MILLING MACHINE

Acer E-mill Model 3VSII

Travel (X,Y,Z) 42″x 12″ x 16″

Power feed (X,Y)

SUPPORT EQUIPMENT

- Master-Cam with 3D swept surface and 4th axis capability.

- Autocad

- 90° Angle Head

- HAAS 5C collet full 4th axis unit with tailstock

- HAAS HR310 12″ face plate full 4th axis unit with additional 12″ chuck & tailstock

- 4th axis double station Trunnion Table

- Horizontal production Band Saws with programmable auto feed up to 12.75″ x 12.6″ flat & 12.75″ diameter

- Vertical Band Saw W/ 20″ throat

- FlexArm hydraulic tapping arm up to 3/4″ tapping capacity.

- 12 ton arbor press

- Internal broaching, SAE & Metric up to 3/4″ & 18mm

- MIG (wire), and TIG welding of Mild Steel, Stainless, and Aluminum

- Deburring, tumbling, glass bead & sand blasting

- Strong relationships with waterjet suppliers

- Strong relationships with laser & bend suppliers

- Strong relationships with coating suppliers (powder coat & paint, anodize, nickel, chrome, black oxide)

- Strong relationships with heat treating suppliers

- Strong relationships with grinding / honing suppliers

- Mechanical Assembly

- Small Product Assembly

- F550 Truck 12′ bed for local pickups and delivery

- Stocking programs

- Most common materials inventory

INSPECTION EQUIPMENT

- Integrated probes in Machining Centers

- Tesa Micro-Hite CMM

- Mitutoyo QM Height stand (24″) accuracy ±(2.4+2.1L/600) μm

- Starret 0″-12″ micrometers w/ qualified standards

- Mitutoyo 13″-18″ micrometers w/ qualified standards

- Pink Granite Grade A Inspection Table W/ certification

- Gauge pins from .011″ – 1.000″

- Gauge block sets with certifications

- Miscellaneous Thread micrometers up to 3″

- Depth micrometers to 12″

- Bore gauges up to 12″

- Thread gauges and wires

- Full inspection reports by request

Engineering:

- Able to work with DWG. DXF. STEP. IGES. And solidworks

- Design

- Reverse Engineering

- Spare parts, OEM replacement

- Prototype Machining

- Jigs and Fixtures

- Tool and Die